Modules And Veneers

FCS was one of the first companies in the UK to develop a Ceramic Fibre Module System.

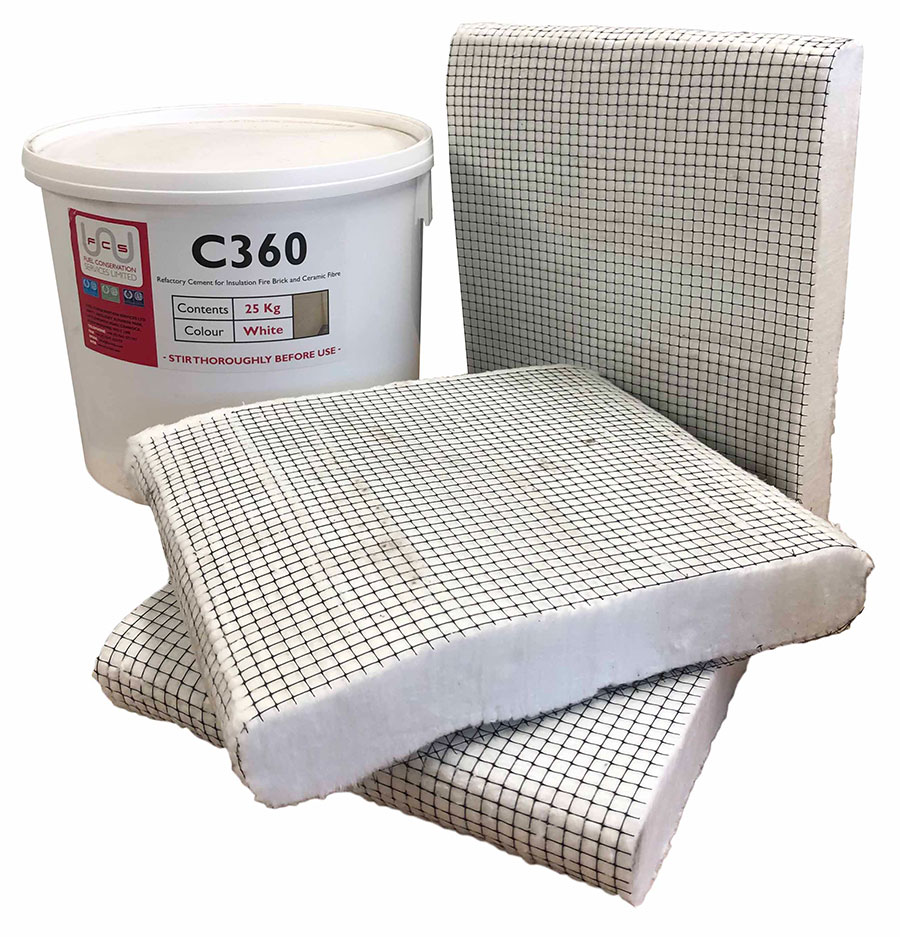

All modules are produced in house to all customer specifications.

Quickfit Modules are designed for fitting to platework or open mesh with ease of installation in mind. The Modules are secured under compression with a polythene sleeve. This sleeve radically reduces dusting of the Module during handling and installation.

The fixings are of heat resisting stainless steel – the central fixing being a channel section so that the fixing point is in contact with the furnace or kiln coldface.

The Module is secured by screwing a self drilling screw through the hole in the channel section.

Quickfit Modules are installed side-by-side in single rows with a ‘U’ shaped ceramic fibre

joining piece between each row to cater for any fibre shrinkage.

Either face of the Module can be used as the hot face dependant upon it’s application and

customer requirements.

All Modules are fitted with a cardboard tube. This is used to locate the shank of the screwgun making location of the screw, through the batten, positive. The tube is removed after fixing.

Once a Quickfit installation has been completed we recommend that, where applicable, the hotface of the lining modules has a complete coating of KC2000.

The coating of KC2000 will not only protect the refractory lining – leading to an extended service life, but its energy reflective quality also will increase the efficiency of the kiln/furnace, resulting in even further energy savings.

Request a call back